Beef Abattoir Guide

Abattoirs, or slaughterhouses, are essential components of the food industry. They transform live animals into consumable meat products. They play a crucial role in meeting the global demand for meat while adhering to strict food safety and animal welfare regulations. This guide will delve into the intricate processes within an abattoir, from the arrival of live animals to the distribution of processed meat products. Paddock to Plate is important to knowing the traceability of the animal during the processing method.

-

Stunners

-

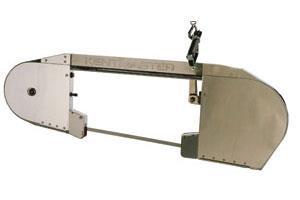

Beef Hock and Horn Cutters

-

Hydraulic Beef Hocker Cutter HC-III

-

Pneumatic Air De-Hiders

-

Hydraulic Beef Head Dropper HC-V

-

Beef Brisket Saws

-

Carcass Cleaning System Vac-San

-

Beef Splitting Saws

-

Circular Breaking Saws

-

Breaking Saws

-

Hydraulic Beef Head Table - Chisel and Jawbone BHT-I

-

Offal Processor, Tripe Washer and Refiner TG 32

Importance of Hygiene and Safety

Maintaining a high level of hygiene and safety is paramount in abattoirs. Stringent protocols are in place to prevent contamination and protect both human and animal health. Regular cleaning, disinfection, and sanitation procedures are conducted throughout the facility. Additionally, employees must adhere to strict hygiene practices, including wearing protective clothing and regularly washing hands.

Types of Abattoirs

Abattoirs can vary in size and specialisation. Some focus on specific animal species, such as beef, pork, or poultry, while others may handle multiple species. The size of an abattoir often determines its capacity and the complexity of its operations.

- Small-scale Abattoirs: Typically serve local communities, processing a limited number of animals.

- Large-scale Abattoirs: Process high volumes of animals and often supply meat to national and international markets.

- Specialised Abattoirs: Focus on specific types of animals or meat products, such as organic, halal, or kosher.

Pre-Slaughter Handling

Animal Transportation and Welfare

The journey to the abattoir should minimise stress for animals. Proper transportation vehicles with adequate ventilation and space are essential. Animals should be provided with food, water, and rest during transport.

Holding Pens and Facilities

Upon arrival, animals are typically held in holding pens before slaughter. These pens must be clean, well-ventilated, and free from hazards. The environment should be calm to reduce animal stress.

Stunning Methods

Stunning is a critical step to render animals unconscious before slaughter. The goal is to inflict minimal pain and distress. Common stunning methods include:

- Electrical Stunning: Involves passing an electrical current through the animal's brain.

- Captive Bolt Stunning: A pneumatic or mechanical device fires a captive bolt into the animal's brain.

The choice of stunning method depends on the animal species and local regulations.

Slaughter Process

The slaughter process begins immediately after stunning. It involves several critical steps:

Stunning to Bleeding

Once an animal is effectively stunned and moved to a bleeding area, the carotid artery and jugular vein are severed to allow rapid blood drainage. Complete blood removal is essential for meat quality and food safety.

Carcass Recovery and Initial Cleaning

After bleeding, the carcass is hoisted on a rail system for further processing. Initial cleaning involves removing excess blood and other contaminants using high-pressure water sprays.

Carcass Processing

Carcass processing involves several stages to transform raw carcasses into marketable meat products.

Splitting the Carcass

The carcass is typically split into two halves along the backbone using a saw. This process facilitates further processing and inspection.

Removal of Organs (Viscera, Pluck, Head)

Internal organs, including the digestive system (viscera), heart, lungs, trachea (pluck), and head, are removed. These by-products are often processed separately for human or animal consumption or converted into other products.

Washing and Sanitising

After organ removal, the carcass undergoes a thorough washing and sanitising process to eliminate blood, hair, and other contaminants. High-pressure water sprays and sanitising agents are used for this purpose.

Inspection and Quality Control

Veterinary inspectors examine the carcasses for signs of disease, abnormalities, or contamination. Carcasses that do not meet quality standards are rejected.

Meat Cutting and Trimming

Carcasses are broken down into various cuts of meat, such as steaks, roasts, and ground meat. Skilled butchers use specialized equipment, including saws, knives, and grinders, to perform these tasks. Trimming excess fat and connective tissue is essential for meat quality.

Packaging

Meat products are packaged in various materials, including plastic, vacuum-sealed bags, and trays. Packaging protects the meat from contamination and extends shelf life.

Storage and Distribution

Meat products are stored in controlled temperature environments to maintain freshness. Refrigerated or frozen storage is used depending on the type of meat and intended shelf life. Once packaged, meat products are distributed to retail stores, restaurants, or other food service establishments.

By-Product Handling

Abattoirs generate various by-products that can be further processed into valuable products or disposed of safely.

Processing of Hides, Bones, Blood, and Other By-Products

- Hides: These are cleaned, salted, or cured for use in leather production.

- Bones: Can be processed into bone meal, gelatin, or other products used in animal feed or industrial applications.

- Blood: Can be dried into blood meal for animal feed or processed into other products.

- Other By-products: Intestines, hooves, and horns can be processed into various products, such as collagen, glue, and fertilisers.

Rendering and Other Value-Added Processes

Rendering is a process that converts animal by-products into tallow, meat meal, and other products through heating and separation. These products are used in various industries, including food, animal feed, and cosmetics.

Sanitation and Hygiene

Maintaining a clean and sanitary environment is crucial in abattoirs to prevent contamination and ensure food safety.

Cleaning and Disinfection Procedures

Regular and thorough cleaning and disinfection are essential throughout the abattoir. High-pressure water systems, detergents, and sanitisers remove blood, fat, and other residues from floors, walls, equipment, and surfaces.

Waste Management

Proper waste management is vital to prevent contamination and odour issues. Solid waste, such as animal carcasses and organs, is collected and disposed of according to regulations. Liquid waste, including blood and wastewater, is treated to remove contaminants before discharge.

Employee Hygiene

Abattoir workers must adhere to strict hygiene practices to prevent contamination of meat products. This includes wearing protective clothing, hairnets, gloves, regular handwashing, and sanitising.

OVERVIEW

Abattoirs play a critical role in the global food supply chain by transforming live animals into consumable meat products. The process involves meticulous attention to hygiene, safety, and animal welfare. From the arrival of animals to the distribution of processed meat, each stage is carefully controlled to ensure food safety and quality.

The journey through an abattoir encompasses a complex series of steps, including pre-slaughter handling, stunning, slaughter, carcass processing, by-product handling, and sanitation. Modern abattoirs employ advanced equipment and technologies to optimise efficiency and minimise environmental impact.

KENTMASTER

It is vital to consult professionals like Kentmaster when setting up an abattoir or maintaining the machinery within. From consultation to conclusion, every piece of equipment necessary to function from start to finish is provided. With experience since the 1940s, no stone is left unturned, and your operation will run seamlessly.