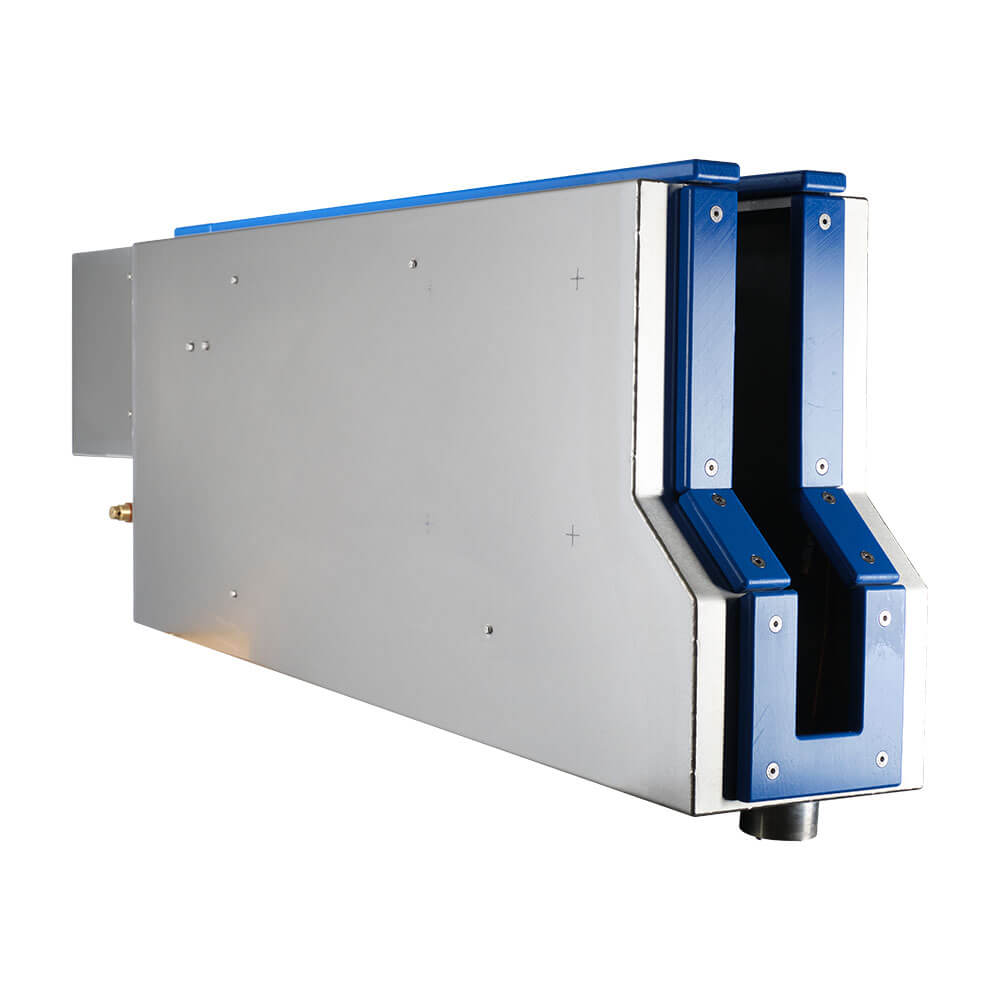

Splitting Saw Steriliser Econoliser

Crafted to supersede traditional constant flow or water bath type sterilisers, our solution offers unparalleled efficiency and performance.

Key Features:

- Achieves an exceptional 95% reduction in water usage compared to constant flow immersion sterilisers, leading to significant cost savings.

- Ensures a minimum 95% reduction in the cost of water heating.

- Virtually eliminates steam production, minimizing the risk of airborne contaminants condensing on surfaces and contaminating carcasses.

- Activated by tool insertion, prioritizing operator safety and ease of use.

- Provides fully automatic operation, delivering consistent results with any operator.

- Incorporates a new easy access design for simplified servicing, minimizing downtime.

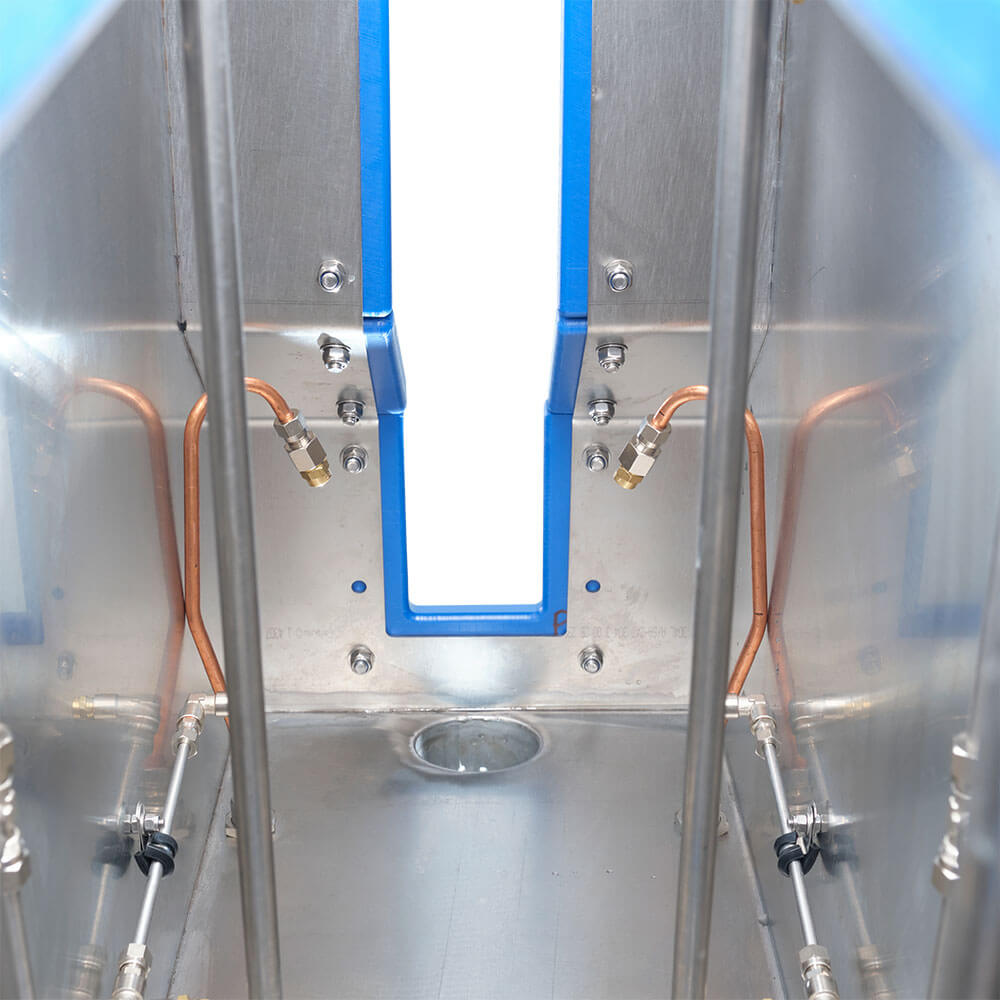

- The built-in water heater guarantees that the water temperature remains consistently above 82°C, regardless of the initial temperature of the water supply (with the setpoint set at 90°C).

- Compatible with all Econoliser models and water temperatures, optimizing efficiency regardless of water temperature.

- Includes pre-sterilization high-pressure rinse cycle to prevent buildup of bone and fat where the blade enters the motor housing.

Options:

- External temperature display provides real-time monitoring of water temperature as it leaves the nozzles.

Specifications:

- Supply Voltage: 240V AC 50/60Hz;

- Max Load Current: 23A;

- Minimum Dynamic Water Pressure: 3Bar;

- Minimum Sterilisation Water Flow Rate: 15L/min;

- Factory Set Sterilisation Cycle Time: 4.5secs;

- Water Used per Sterilisation Cycle: ≤0.84L;

- High-pressure rinse cycle dynamic water pressure: 12bar — 20Bar;

- High-pressure minimum flow rate: 25L/min;

- Factory Set High-pressure rinse cycle time: 2secs;

- High-pressure Water Used per Cycle: 0.8L;