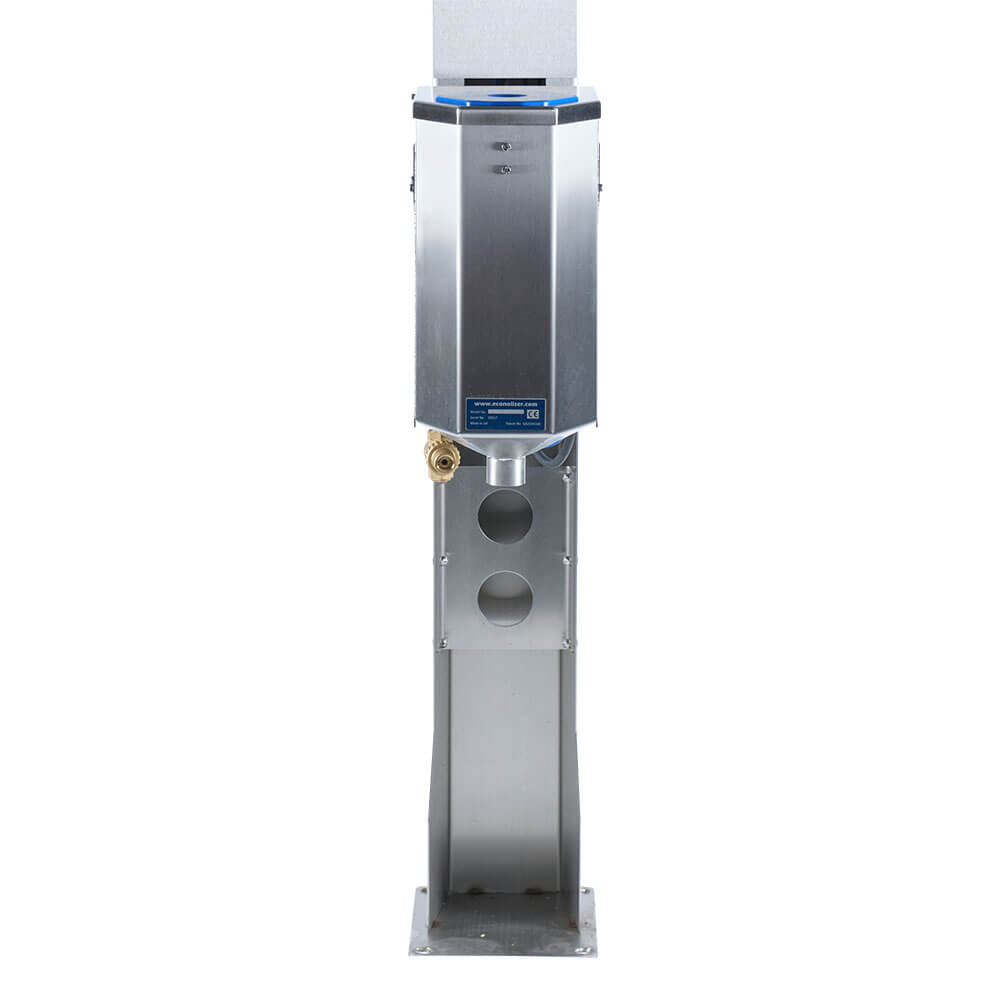

Steriliser Econoliser Twin Knife

Introducing an innovative solution designed to replace traditional constant flow or water bath type sterilisers. This unit sanitises one knife while the other is in use, or both knives simultaneously, maximizing efficiency and hygiene.

Key Features:

- Achieves a remarkable 95% reduction in water usage compared to constant flow immersion sterilisers, leading to substantial cost savings in water heating;

- Virtually eliminates steam production, preventing condensation on overhead equipment and dripping onto carcasses;

- Eliminates the need for a tank of hot water, ensuring zero risk of scalding and providing a more comfortable working environment;

- Activates automatically upon knife insertion, offering safe and easy operation for operators;

- Fully automatic operation ensures consistent results with any operator;

- Innovative cassette design allows for easy servicing, minimizing downtime;

- New knives maintain their edge longer as they are not immersed in hot water, preventing annealing;

- Equipped with a built-in electric water heater, allowing flexibility in water supply temperature from cold (0°C) to hot (up to 90°C), ensuring water temperature remains above 82°C for effective sterilisation;

- Efficiently heats only the water needed for each cycle, reducing energy costs;

- Supports the use of electric from renewable sources, enabling users to reduce their dependence on fossil fuels and lower their carbon footprint.

Options:

- Mounting Column;

- External temperature display to monitor water temperature during sterilisation;

- 4-nozzle manifold for longer knives;

- Special manifold for exceptionally dirty knives.

Specifications:

- Mains Electric Supply: 230/240V AC 50/60Hz;

- Maximum Load: 11A;

- Water Supply Temperature: ≥82°C;

- Dynamic Water Pressure Minimum: 3Bar;

- Sterilisation Minimum Water Flow Rate: 4.2L/min;

- Factory Set Sterilisation Cycle Time: 4.5 seconds;

- Water Used per Sterilisation Cycle: 0.140L.